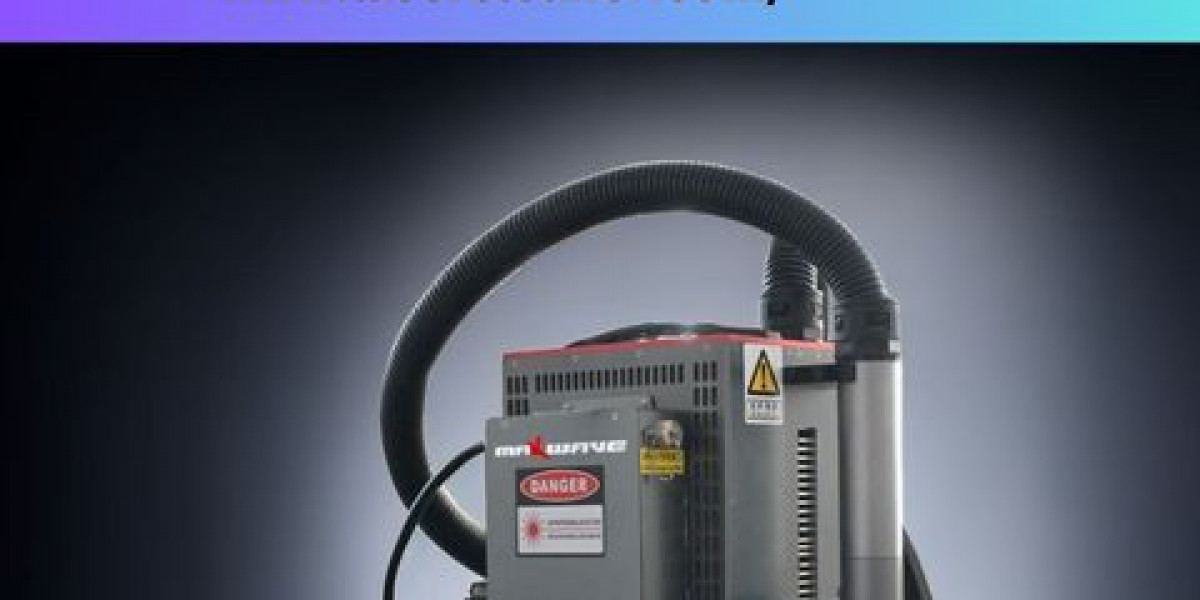

The laser cleaning machine price varies depending on several factors, including power output, brand reputation, and additional features. Entry-level models may start at around $10,000, while industrial-grade systems can exceed $100,000. But why such a wide range?

Power Output – Higher-wattage machines (e.g., 500W-1000W) are more expensive but offer faster cleaning speeds and can handle tougher materials like rust and heavy coatings. Lower-wattage models (50W-200W) are more affordable but suitable for lighter applications.

Brand & Build Quality – Established manufacturers often charge a premium for reliability and after-sales support. Cheaper alternatives may cut corners on components, leading to higher maintenance costs.

Automation & Customization – Machines with robotic arms or integrated software for precision cleaning command higher prices due to advanced functionality.

Why the Initial Price Doesn’t Tell the Whole Story

While traditional cleaning methods like sandblasting or chemical cleaning may seem cheaper initially, they come with hidden costs:

Labor Expenses – Manual cleaning requires more workforce, increasing operational costs.

Consumables – Sandblasting media, chemicals, and abrasives need frequent replacement.

Environmental & Safety Compliance – Disposal of hazardous waste and worker safety measures add to expenses.

A laser cleaning machine eliminates these recurring costs. It requires no consumables, reduces labor needs, and operates with minimal waste, making it a cost-effective solution in the long run.

Calculating Return on Investment (ROI)

To justify the laser cleaning machine price, businesses must evaluate ROI. Here’s a simplified breakdown:

Reduced Operational Costs – No need for abrasive materials or chemicals.

Faster Processing – Higher efficiency means more jobs completed in less time.

Minimal Downtime – Low maintenance requirements ensure continuous operation.

For example, a mid-range $50,000 laser cleaning machine could pay for itself within 1-2 years by slashing consumable expenses and boosting productivity.

Choosing the Right Machine for Your Budget

Not every business needs a top-tier laser cleaning system. Assess your requirements:

Small Workshops – A 50W-100W machine may suffice for light rust removal.

Industrial Applications – Heavy-duty 500W+ models are ideal for large-scale operations.

Used/Refurbished Options – Can cut costs by 30-50% while maintaining performance.

Final Thoughts

The laser cleaning machine price should be viewed as an investment rather than an expense. While the initial outlay may seem high, the long-term savings, efficiency, and environmental benefits make it a financially sound choice. By analyzing your specific needs and calculating potential ROI, you can select a machine that delivers maximum value without overspending.

If you're ready to explore laser cleaning solutions, request a quote today and discover how this technology can revolutionize your cleaning processes while saving money in the long run!