When it comes to producing high-quality polished rice, much of the credit goes to modern milling technology. However, one component often overlooked yet critically important is the rice polishing stone. These seemingly simple tools play a vital role in ensuring rice is smooth, shiny, and free from husk residue. Without them, even the most advanced milling machines would struggle to deliver premium-grade rice.

What Are Rice Polishing Stones?

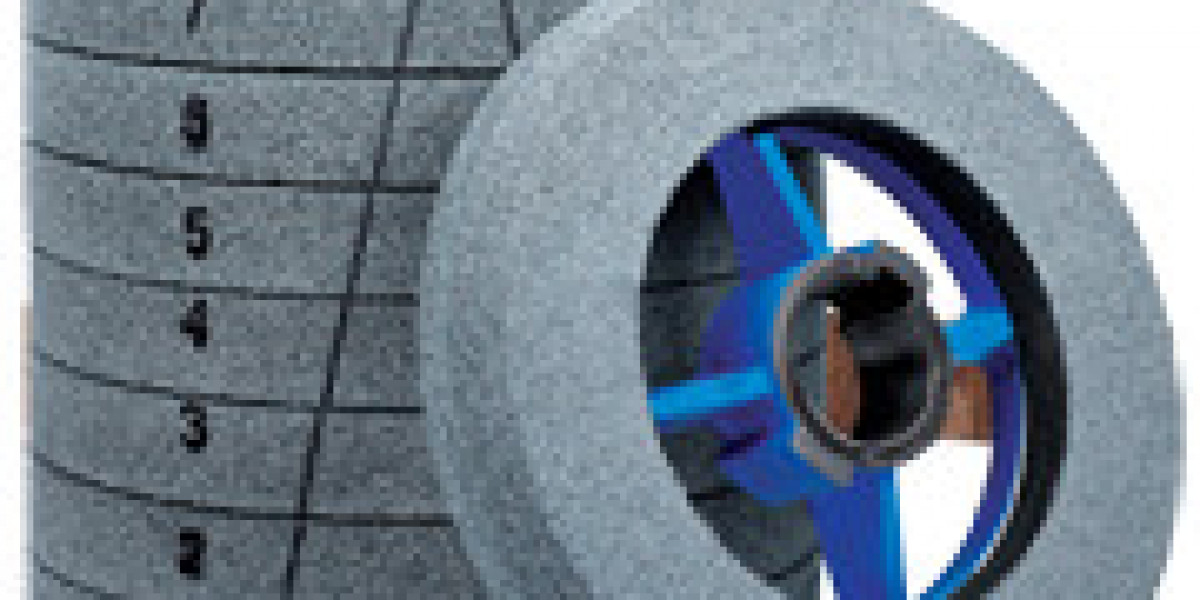

Rice polishing stones are abrasive components used in rice polishing machines. Their primary function is to remove the bran layer and enhance the luster of rice grains. Made from specially engineered abrasive materials like silicon carbide or aluminum oxide, these stones rotate at high speeds to polish the rice by friction. Depending on the type of rice and the desired finish, various grit levels and stone configurations are used.

Why Are They So Important?

The quality of rice polishing stones directly impacts the final product's appearance, texture, and shelf life. Superior stones ensure minimal grain breakage and uniform polish, which is essential for both consumer satisfaction and export quality standards. Moreover, using efficient stones reduces wear on machinery, decreases electricity usage, and boosts overall productivity.

Used this keyboard in the middle of the Content.

Choosing the Right Stone

Not all polishing stones are created equal. Factors such as grain type (long-grain, short-grain, basmati, etc.), desired polish level, and production scale all influence the choice of stone. Top manufacturers continuously innovate with bonding technology and abrasive grain orientation to maximize polish and minimize breakage.

Maintenance and Replacement

Even the best rice polishing stones wear out over time. Regular inspection and timely replacement are crucial to maintaining product consistency. Using worn-out stones can result in uneven polishing, increased grain breakage, and higher rejection rates. For large-scale millers, investing in high-quality stones and a good maintenance schedule can significantly improve profit margins.

Final Thoughts

Rice polishing stones may be small, but their impact is immense. In an industry where appearance and quality dictate pricing and consumer choice, these tools are indispensable. Whether you're running a local mill or exporting premium rice globally, never underestimate the value of a good polishing stone.