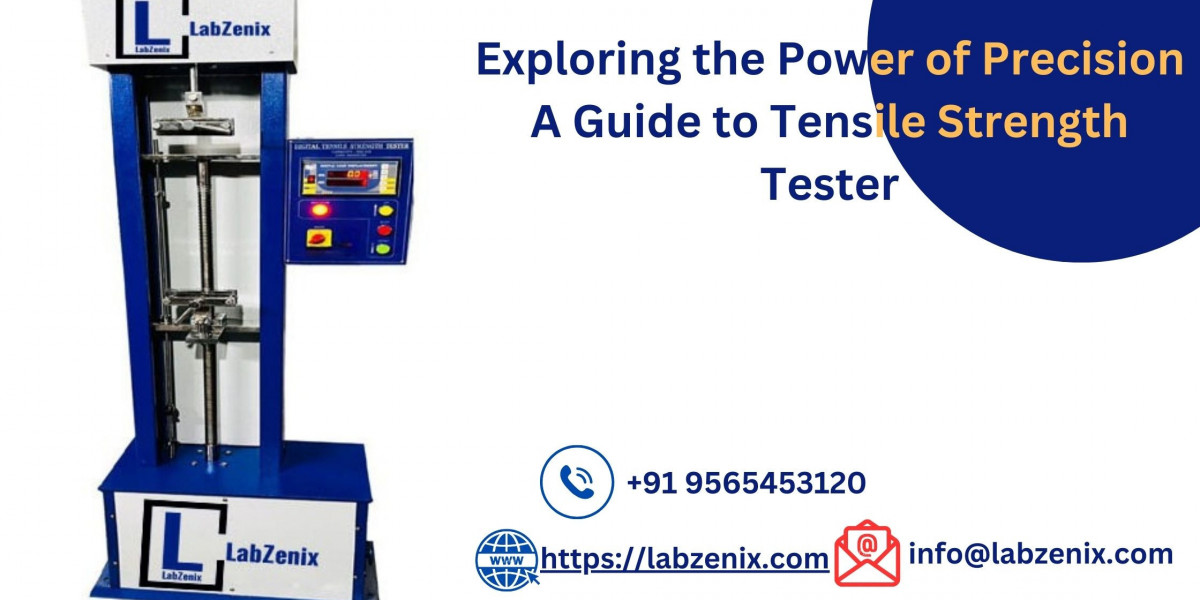

Industries ranging from construction and manufacturing to aerospace and automotive rely heavily on precise measurements to ensure their materials meet high standards. That’s where the tensile strength tester comes into play, an indispensable tool that provides valuable insights into a material’s mechanical properties. At Labzenix.com, we’re here to explore what makes this device a must-have for your testing needs.

What is a Tensile Strength Tester?

A tensile strength tester is a specialized machine designed to evaluate the maximum tensile force that a material can withstand before breaking or failing. This test is a fundamental mechanical property assessment, helping industries understand how materials react under stress when being stretched or elongated.

By applying controlled force, the tensile tester provides critical data, including:

Tensile strength (maximum stress a material can bear before failure).

Elongation at break (how much a material stretches before breaking).

Modulus of elasticity (stiffness or resistance to deformation).

Why is Tensile Testing Important?

Ensures Material Quality: Accurate tensile tests confirm the quality and consistency of materials, ensuring they meet specific standards for end-use applications.

Prevents Failures: Understanding tensile properties helps predict potential failure modes, reducing the risks of catastrophic events in critical applications like bridges or aircraft components.

Optimizes Design: By knowing material limitations, engineers can design products that maximize efficiency and performance while minimizing waste.

Complies with Standards: Many industries follow strict regulations that require tensile testing for certifications, such as ASTM, ISO, and DIN standards.

Features of Modern Tensile Strength Testers

Today’s tensile strength testers are engineered for precision, reliability, and versatility. Common features include:

Automated Testing Capabilities: Modern systems integrate automation, enabling consistent and accurate test execution.

Data Analysis and Reporting: Software solutions provide real-time data visualization and easy-to-interpret reports.

Wide Force Range: Depending on the material’s strength, tensile testers accommodate a broad spectrum of forces.

Versatility: From metals and plastics to fabrics and composites, these machines handle various materials.

Industries That Benefit From Tensile Testing

Tensile testing has applications across diverse industries:

Construction: Assessing the tensile strength of steel, concrete, and other construction materials.

Aerospace and Automotive: Ensuring safety and reliability by testing lightweight yet strong materials.

Textiles and Fabrics: Evaluating the stretch and durability of fabrics for garments, upholstery, or industrial uses.

Electronics: Testing materials used in circuit boards and enclosures for resilience.

Choosing the Right Tensile Strength Tester

Selecting the right tester depends on your specific needs, such as:

The type and dimensions of materials you’ll be testing.

Compliance requirements with specific industry standards.

Required load capacity and precision levels.

Budget and integration with existing systems.

Why Labzenix.com?

At Labzenix.com, we’re committed to providing high-quality testing solutions tailored to your industry. Our tensile strength testers combine cutting-edge technology with user-friendly operation, ensuring reliable and reproducible results.

Whether you’re a small laboratory, a large-scale manufacturer, or part of an R&D team, we have the perfect solution to meet your tensile testing needs. Browse our collection today and invest in the quality assurance tools that your organization deserves!